| Kingflex Dimension | |||||||

| Thickness | Width 1m | Width 1.2m | Width 1.5m | ||||

| Inches | mm | Size(L*W) | ㎡/Roll | Size(L*W) | ㎡/Roll | Size(L*W) | ㎡/Roll |

| 1/4" | 6 | 30 × 1 | 30 | 30 × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | 20 × 1 | 20 | 20 × 1.2 | 24 | 20 × 1.5 | 30 |

| 1/2" | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| 3/4" | 19 | 10 × 1 | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | 8 × 1 | 8 | 8 × 1.2 | 9.6 | 8 × 1.5 | 12 |

| 1 1/4" | 32 | 6 × 1 | 6 | 6 × 1.2 | 7.2 | 6 × 1.5 | 9 |

| 1 1/2" | 40 | 5 × 1 | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

| Kingflex Technical Data | |||

| Property | Unit | Value | Test Method |

| Temperature range | °C | (-50 - 110) | GB/T 17794-1999 |

| Density range | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Water vapor permeability | Kg/(m.s.pa) | ≤0.91×10 ﹣¹³ | DIN 52 615 BS 4370 Part 2 1973 |

| μ | - | ≥10000 | |

| Thermal Conductivity | W/(m.k) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

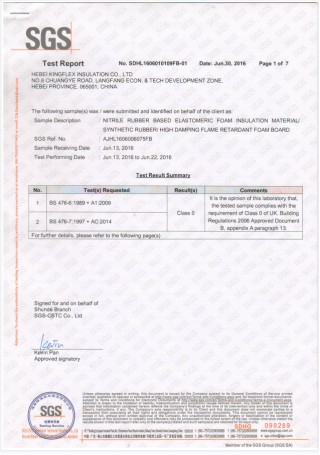

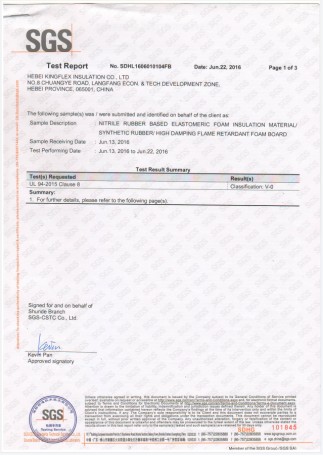

| Fire Rating | - | Class 0 & Class 1 | BS 476 Part 6 part 7 |

| Flame Spread and Smoke Developed Index |

| 25/50 | ASTM E 84 |

| Oxygen Index |

| ≥36 | GB/T 2406,ISO4589 |

| Water Absorption,%by Volume | % | 20% | ASTM C 209 |

| Dimension Stability |

| ≤5 | ASTM C534 |

| Fungi resistance | - | Good | ASTM 21 |

| Ozone resistance | Good | GB/T 7762-1987 | |

| Resistance to U.V. and weather | Good | ASTM G23 | |