Excellent performance. The insulation pipe is made of nitrile rubber and polyvinyl chloride, free of fiber dust, benzaldehyde and chlorofluorocarbons. In addition, it has low electrical and thermal conductivity, good moisture resistance and fire resistance. Excellent tensile strength Anti-aging, anti-corrosion Easy to install. Insulated pipes can be easily installed on new pipes as well as used in existing pipes. You just cut it and glue it on. Moreover, it has no negative effect on the performance of the insulation tube.

Kingflex rubber foam product is generally black in color, other colors are available upon request. The product comes in tube, roll and sheet form. The extruded flexible tube are specially designed to fit the standard diameters of copper, steel and PVC piping. Sheets are available in standards precut sizes or in rolls.

Kingflex rubber foam product is generally black in color, other colors are available upon request. The product comes in tube, roll and sheet form. The extruded flexible tube are specially designed to fit the standard diameters of copper, steel and PVC piping. Sheets are available in standards precut sizes or in rolls. Technical Data Sheet

| Kingflex Technical Data | |||

| Property | Unit | Value | Test Method |

| Temperature range | °C | (-50 - 110) | GB/T 17794-1999 |

| Density range | Kg/m3 | 45-65Kg/m3 | ASTM D1667 |

| Water vapor permeability | Kg/(m.s.pa) | ≤0.91×10 ﹣¹³ | DIN 52 615 BS 4370 Part 2 1973 |

| μ | - | ≥10000 | |

| Thermal Conductivity | W/(m.k) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

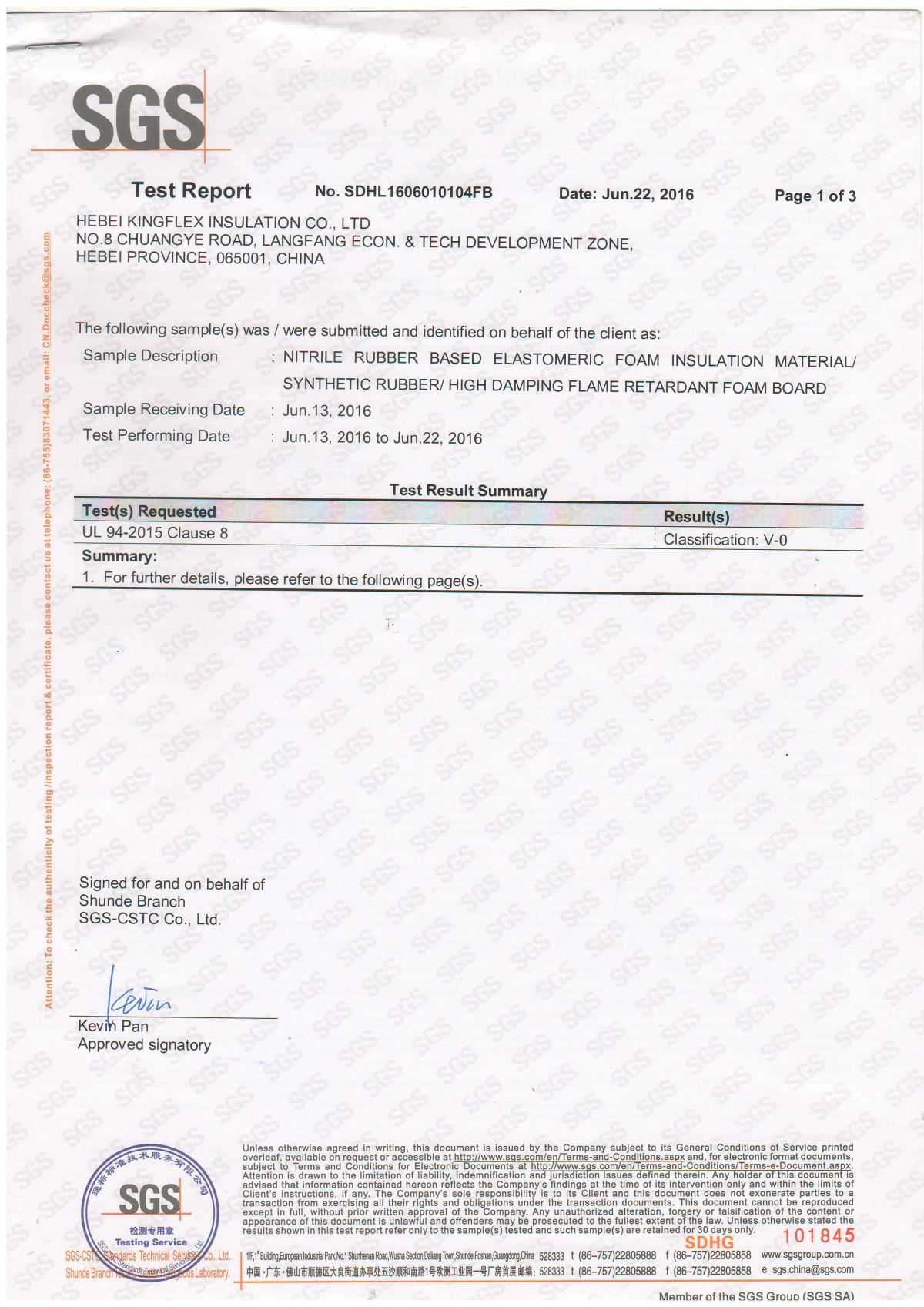

| Fire Rating | - | Class 0 & Class 1 | BS 476 Part 6 part 7 |

| Flame Spread and Smoke Developed Index | 25/50 | ASTM E 84 | |

| Oxygen Index | ≥36 | GB/T 2406,ISO4589 | |

| Water Absorption,%by Volume | % | 20% | ASTM C 209 |

| Dimension Stability | ≤5 | ASTM C534 | |

| Fungi resistance | - | Good | ASTM 21 |

| Ozone resistance | Good | GB/T 7762-1987 | |

| Resistance to U.V. and weather | Good | ASTM G23 | |